Txheej txheem ntau lawm thiab cov txheej txheem ntawm kub-rolled ribbed steel bar

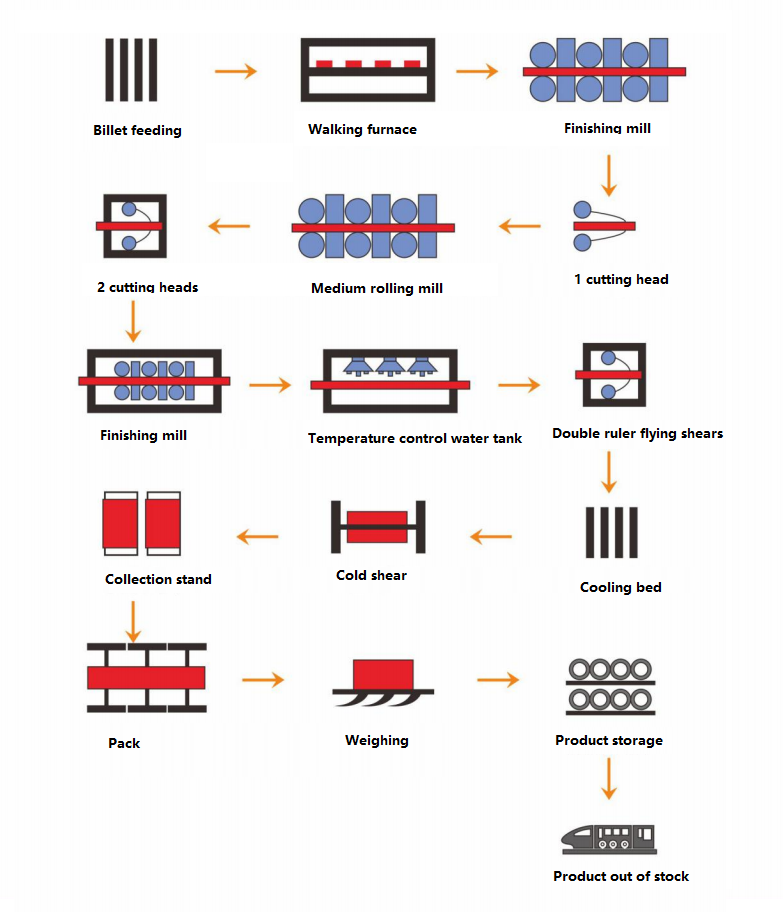

Cov txheej txheem tom qab:

Nyob rau hauv qhov tam sim no rebar ua lag luam, HRB400E cov account rau ntau dua. Lub microalloy ntxiv dag zog txoj hau kev yog qhov tseem ceeb los tsim HRB400E hauv ntiaj teb. Lub microalloloalloy feem ntau yog vanadium alloy lossis niobium alloy, uas noj ntau ntawm alloy cov peev txheej txhua txhua xyoo. Vim muaj tsawg cov ntxhia cov khoom siv uas muaj vanadium thiab niobium, muab cov khoom siv alloy no nruj. Yog li ntawd, yog tias cov ntsiab lus alloy ntawm HRB400E steel bar tuaj yeem raug txo kom tsawg, nws yuav tsim kev lag luam loj thiab muaj txiaj ntsig zoo.

Nyob rau hauv cov thev naus laus zis uas twb muaj lawm, ob-hlau xaim xaim cov kab ntau lawm tsis muaj zog los tsim cov khoom siv Vanad400E, thiab cov qhab nia loj ntawm cov neeg Vanadium yog 0.035% rau 0.045%.

Suav pente cent cn10435774357741a qhia tawm ib hom HRB400E muaj zog av qeeg-resistant hlau kauj thiab nws txoj kev tsim khoom. Los ntawm cov qauv, cov khoom tiav lawm yog tsim los ntawm kev txo qis thiab xaws cov hlau yob, cov qauv no tsis haum rau cov kab ntau lawm tsis muaj kev txo cov ceg tawv. Suav patent CN110184516A Muab cov hlau npaj siab φ6mm ~ HRB400E coiled ntsia hlau. Nrog kev pab ntawm cov muaj zog rolling muaj peev xwm ntawm cov khoom siv, tsawg kub yob pib los ntawm kev kub kub, thiab kev ntau lawm tsis muaj microalloying yog pom tau. Qhov tsis zoo ntawm txoj kev no yog qhov yuav tsum tau ua rau lub neej muaj zog, thiab cov nyiaj tau los ntawm cov kab hlau φ6mm ~ HRB400E coil tsim los ntawm hom qauv no yog nyiaj seem. Tsis paub txaus ntau, nws yog qhov nyuaj rau lav cov kev ua tau zoo ntawm kev ua tau zoo.

Kev Siv Ntsiab Lus:

Tam sim no muaj lub hom phiaj tam sim no los ua cov khoom siv kub ntawm cov khoom siv kub

Cov txheej txheem txuj ci ntawm qhov tsim tam sim no:

Txoj kev ntau lawm ntawm Ribbed steel bar, qhov tshwj xeeb ntawm ribbed steel hlau, txias - cua txias - cua txias sau cov rooj-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv-kiv - cua txias txias; Cov tshuaj lom neeg muaj feem pua ntawm cov hlau yog c = 0.20% ~ 0.60%, tus lej 2,000%, tus so yog fe thiab unavoidable kev hlab nkab thiab Cov kauj ruam tseem ceeb ntawm cov txheej txheem muaj xws li: Lub cua sov kub yog 1070 ~ 1130 ℃, qhov prefinishing dov kub yog 970 ~ 1000 ℃, thiab cov finishing yob kub yog 840 ~ 1000 ℃. 880 ℃; tso kub 845 ~ 875 ℃; Thaum kawg dov qhov kub yog hauv qab cov recrystallization kub ntawm Austenite cheeb tsam; Sai sai txias los ntawm cov kiv cua ntawm huab cua-txias cov ntaub pua av, cua ntim yog 100%; Qhov ntsuas kub ntawm lub hau yog 640 ~ 660 ℃, qhov ntsuas kub, ntawm kev tiv thaiv cov cua sov yog 600 620 ℃, thiab lub sijhawm ntawm kev tiv thaiv tshav kub yog 45 ~ 55s.

Lub hauv paus ntsiab lus ntawm kev tsim muaj: hauv qhov ntsuas kub ntawm 840-880 ℃, tus austenite nplej yog elongated los ntawm rolling deformation, tab sis recrystallization tsis tshwm sim. Txawm li cas los xij, deformation bands yog tsim nyob rau hauv lub txiv qaub ua ke, thiab muaj kuj deforment grainaries los faib cov elongated Austenite nplej. Thaum lub sijhawm hloov pauv ntawm Austenite mus rau ferrite, ob lub elongated Austenite gragaries defitality, uas ua rau rerrite tom qab hloov pauv. Tsawg qhov kub dov rau hauv cov zeb tiav kom txo cov ntaubo rolling thiab nruab nrab mills thiab ua ntej-txhij cov hauj lwm ntawm cov khoom siv.

Cov kev muaj txiaj ntsig zoo ntawm kev tsim muaj muaj raws li hauv qab no: los ntawm kev ntxiv ib qho kev txhawb nqa me me tom qab dov tawm tom qab dov, thiab ua si lub luag haujlwm ntawm nag lossis daus. Lub kub-dov hlau tus pas nrig muaj lub zog tensile muaj lub zog ntawm 420-500MPA, ib qho txiaj ntsig zoo, thiab agt> 10%, uas ua kom muaj kev sib haum txaus. Cov txiaj ntsig lub zog yog ruaj khov, thiab kev ua yeeb yam muaj peev xwm ua tau zoo yog ib qho siab dua 99%. Cov kev tsim muaj cov thev naus laus zis uas lub tshuab sib tw yog qhov nyuaj tsis tau txo qis, txo tus nqi ntau lawm, thiab coj txog cov txiaj ntsig ntau dua kev khwv nyiaj txiag.

Cov hau kev kawm kom ntxaws

Cov ntsiab lus ntawm cov tsim tam sim no yog piav qhia ntxiv hauv qab no nrog rau cov embodiments.

Txoj kev ntau lawm ntawm ib pawg ntawm cov hlau siab φ8mm ~ φ10mmhrb400E coiled qwj. Tus txheej txheem Rolling yog: Tawm kub: 1080 ~ 1120 ℃, nkag mus rau hauv rwb thaiv tsev hluav taws xob: 850 ~ 660-42, 55 Thiab nws txias lawm. Cov tshuaj lom neeg muaj pes tsawg leeg ntawm cov pas hlau ntawm lub embodiment ntawm cov cuab yeej tam sim no muaj nyob rau hauv lub rooj 1, thiab cov neeg ua haujlwm ntawm cov tsim muaj tam sim no muaj qhia hauv Table 2.

Tshuaj lom neeg tshuaj (wt%) ntawm cov pas nrig hlau ntawm lub rooj piv txwv

Cov Lus 2 Cov Khoom Siv Cov Khoom Siv Ntawm Piv Txwv Hlau Hlau Rods

Cov qoob loo tau los ntawm cov hlau siab φ8mm ~ φ10mmhrb400E, lub zog ua ntej yog nyob rau hauv ntau dua 1.35, thiab cov duab kos duab yog feem ntau yog ferrite thiab Pearlite. , kev ua tau ruaj khov, muaj peev xwm txaus, muaj txiaj ntsig zoo rau kev txo cov kab ntau ntxiv rau cov kab ntau lawm cov kab nrog cov khoom qub.

Cov Nta Cov Txuj Ci:

1. The production method of hot-rolled ribbed steel bar, the wire rod specification is φ8mm~φ10mm, and the technological process includes heating – billeting – rough rolling – medium rolling – cooling – pre-finishing – cooling – finishing – cooling – spinning – air Cold roller table—collecting coil—slow cooling, characterized in that: the chemical composition mass percentage of steel is c=0.20%~0.25%, Si = 0.40% ~ 0.50%, mn = 1.40% ~ 1.60, tus so yog fe tsib yog fe thiab unavoidable kev hlab nkab; Cov txheej txheem tseem ceeb txheej txheem suav nrog: Tapping kub yog 1070 ~ 1130 ° C, qhov ua ntej-finishing kub yog 970 ~ 1000 ° C, thiab cov finishing dov yog nqa tawm. Qhov kub yog 840 ~ 880 ℃; Lub tig kub yog 845 ~ 875 ℃; Qhov kawg rolling kub yog qis dua cov recrystallization kub ntawm austenite cheeb tsam; Nws yog sai sai txias los ntawm tus kiv cua ntawm cov huab cua txias cov rooj, thiab huab cua ntim yog 100%; Lub rooj rau cov menyuam yog insulated los ntawm kev kaw cov rwb thaiv tsev npog, qhov kub ntawm kev nkag mus rau lub rwb thaiv tsev npog yog 600 620 ℃, thiab lub sijhawm hauv lub suab nrov npog yog 45 ~ 55s.

Kev Qhia Txog Lub Ntsiab Lus

Txoj kev ntau lawm ntawm kub-ribbed steel bar, lub caij nplooj ntoos hlav steel yog c = 0.60%, purs0.045%, v = 0.015% ~ 0.020%, Tus so yog fe thiab unavoidable impemes; Cov txheej txheem Rolling yog: Lub cua sov sov yog 1070 ~ 1130 ℃, thiab ua ntej-tiav yog nqa tawm. Lub yob kub yog 970 ~ 1000 ℃, cov ntawv ntsuas kub tiav yog 840 ~ 880 ℃; Lub tig kub yog 845 ~ 875 ℃; Qhov kawg dov qhov kub yog qis dua cov recrystallization kub ntawm cov avustenite cheeb tsam; %; Tom qab kaw cov rwb thaiv tsev npog ntawm cov menyuam, qhov kub ntawm kev nkag mus rau lub rwb thaiv tsev npog yog 640 ~ 660, thiab lub sijhawm nyob hauv lub rwb thaiv tsev npog yog 45 ~ 55s. Los ntawm kev ntxiv ib qho nyiaj me me ntawm V Alloy thiab TEAMLING ntawm tsawg kub, qhov kev tsim tawm tsis yog ua kom muaj kev lag luam ruaj khov ntawm cov khoom siv, tab sis kuj txo cov ntsiab lus alloy thiab tus nqi.

Lub sij hawm Post: Aug-30-2022